end wall flashing detail

Use minimum 019 in. Cross-Flute Metal Deck Termination.

Apply sealant to the inside-top corners of the rough opening at the header Then install the window and flashing in the same manner as shown in Figure 1 steps 3 through 6.

. High Wall Flashing Detail wih Intermittent Fastening. Duro-Guard Fan Fold Fastening. The wallplate is then used to secure the rafter to.

Peel Stick Flashings. Through-wall flashing is used in many areas of the country as shown in Figure 9. The eave trim is located at the end of the roof panel near the top of the wall panel creating a beautiful appearance it also guiding the rainwater which prevents it from falling on the wall panel and windows.

The wallplate is secured to the internal wall separated by DPC. Aluminum is the most common material for window cap flashing and other wall flashings in the US because it is inexpensive and works pretty well in typical conditions. The cap flashing is attached to the base flashing by blind riveting.

Base of Wall Single Wythe Block Flashing at Inside Face. 3Gable trim Gable trim is a metal waterproof panel used at the intersection of roof panels and wall panels along the edge of the. Every TotalFlash job includes free services to help make purchasing and installation headache-free including expert takeoffs bid help and custom panel sizing for wall.

ArcFlash Home Stretch Water Based Liquid Adhesive. It is designed for use on dry surfaces to condition them so that the substrate is suitable for the application of self-adhering. Poly Wall manufactures a market leading line of waterproofing and air barrier membranes designed to enhance the integrity of your structure.

When air sealing around the. Floating The next-to-last stage in concrete work when you smooth off the job and bring water to the surface by using a hand float or bull float. Fastened - General Details.

Roof Area Divider - Curb Type. Both the air control layer and the vapor control layer occur through the depth of the closed-cell spray foam insulation CCSPF. Base of Wall Detail Single Wythe Block Split Base Course November 2 2015 020100312.

Do not seal the outlet end of the flashing - we want any water that enters the wall to run on the outside of the vertical flashing meet the sloped near-horizontal bottom bend of that flashing and run out over and past the end of the projecting concrete slab or foundation in other applications. And TotalFlash is more than just a product. Pan flashing should extend up the rough jamb at least 6 in.

As shown in Fig. Another method of flashing a concrete wall is to cast the cap flashing into the wall. The first step to detailing the base of a brick-veneer wall is to install a through-wall flashing which extends down the sheathing and out across the support ledge often a concrete extension of the foundation but may also be formed with angle-iron.

Insulation and Recover Fastening. Wall with Self-Terminating ParaproParaflex 531 Liquid Flashing. However aluminum flashing is not recommended for use in contact with pressure.

Joints are soldered or sealed see Figure 2. It is constructed so. Flashing at ledger board connections see Page 14 shall be copper with copper nails only stainless steel UV resistant plastic or galvanized steel with a G-185 coating.

Custom-Fabricated Deck Sheet Seaming. A notch is taken out of the rafter known as the birds mouth ensuring a strong fixing which can then be secured. Weeps spaced a maximum of 24 OC.

Bend one end of each strip over roughly 34 to 1 but do not hammer it tightly-flat. The flashing must typically rise at least 8 from the low point at the exterior face of the building to the high point inside the wall. Exterior walloverlap the pan flashing by at least 2 in.

ROT SHIELD Joist Tape. 5-3 the water-shedding surface occurs at the CMU wall face. An alternate base flashing fastening method is to use cleats spaced at 12 OC.

TotalFlash is suitable for use at all flashing locations including base of wall above exterior wall openings and bond beams in parapet walls and wherever flashing is desirable. End dams are constructed by cutting and folding the flashing material. Wall Flashing with Coated Metal Edge.

Fastening into Metal and Wood Decks. An alternative to fabricated valley cleats is the use of roofing nails whose head is set to pin down the edge of the valley flashing. Flashing Sheet metal or other material used in roof and wall construction to protect a building from water seepage.

Use of pea gravel is recommended behind brick. Through-wall flashing is used at all points where moisture may enter the wall and in selected places particularly susceptible to water damage. However the bond-breaking effects of this type of detail need to be evaluated in regard to the.

It is a roll-type product and the membranes controlled thickness is fabricated from cross-laminated polyethylene bonded to specially modified asphalt. Copper Receiver Cast in Concrete Wall. Wall Lite Flashing Peak Flashing 26 ga.

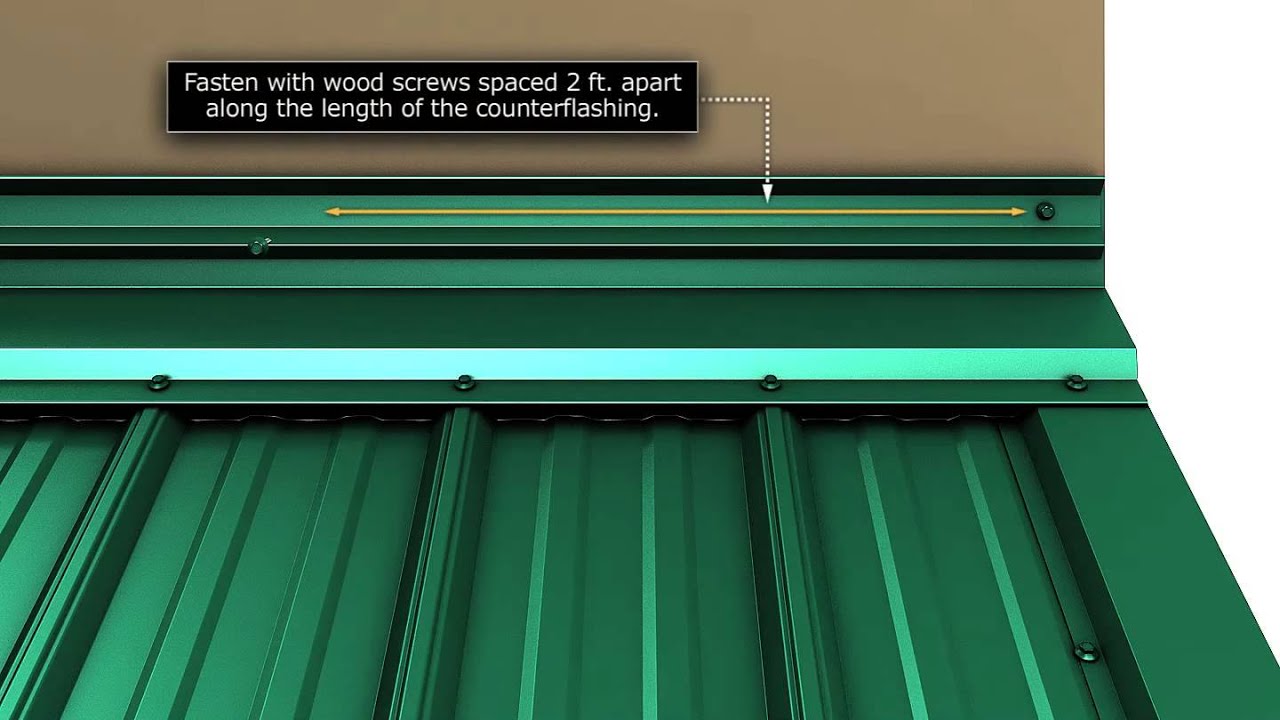

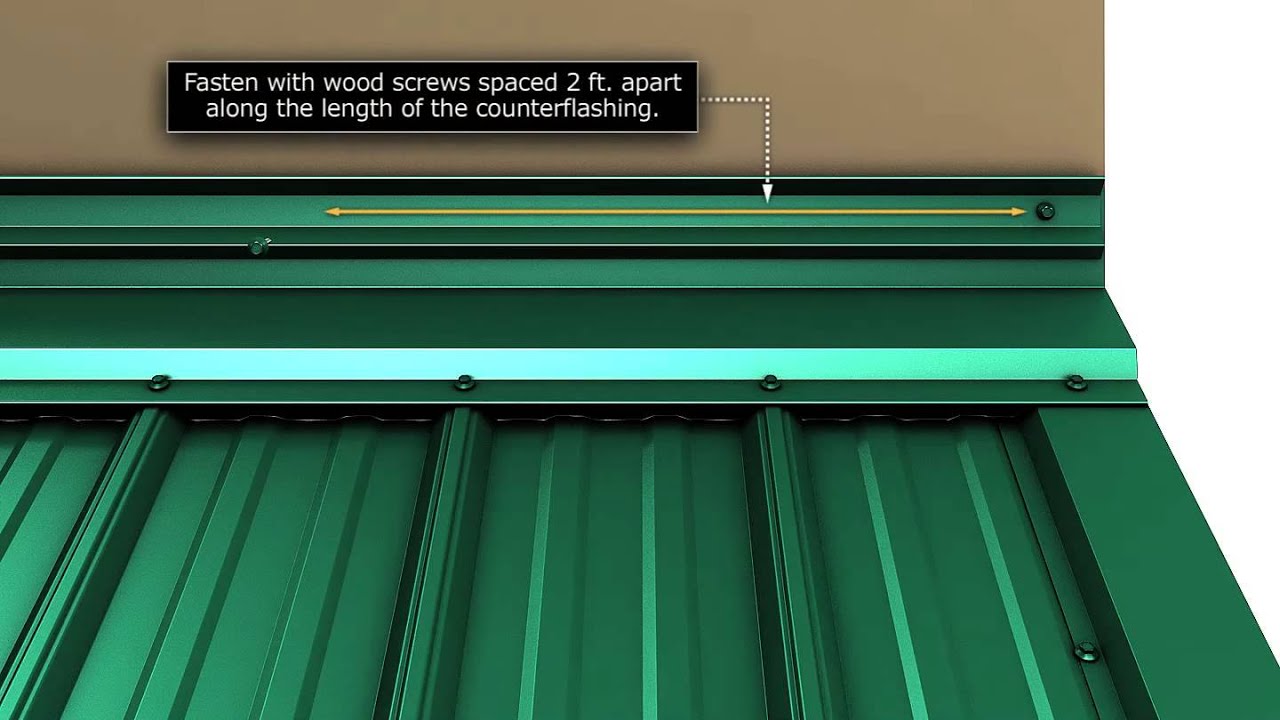

Supporting the sloped nearly-horizontal bend of the wall-bottom flashing. High Wall Flashing Detail with Plates and Fasteners. Floating Wall A non-bearing wall built on a concrete floor.

The water control layer exists within the CMU wall structure. AIR-SHIELD self-adhering airvapor barrier 40 mils thick and liquid moisture barrier is part of a total W. And onto the wall surface at least 2 in.

Parafast RhinoBond Base Tie-In at Angle Change. The lower end of the flashing is hemmed and held by cleats at 12 OC. Poly Wall Home Stretch WB Liquid Adhesive is a polymer emulsion based adhesive which is specifically formulated to provide excellent adhesion with all the Poly Wall waterproofing and flashing membranes under many kinds of surface conditions.

Meadows system to complete the building envelope. Permissible as noted in this document plastic composites must bear a label indicating its compliance with ASTM D. Flashing of single wythe walls at lintels foundations and bond beams is accomplished in the same manner as shown in Figure 4 while sills are shown in Figure 6.

Plastic composites are materials composed of bound wood and plastic fibers. Stock the heavier the aluminum the better and prefinished aluminum will hold up better than mill finish. The cleat bent-over edge is then slipped into the bent-over edge seam of the valley flashing tapped gently flat - not very tight - and its other end nailed to the roof deck.

Eaves Detail The eaves detail shows where the roof members and coverings meet the wall of the dwelling. The control layers for typical system details are also provided adjacent to each detail at the end of this chapter. Wall Base Termination Detail.

End dams should be constructed wherever flashings terminate within a wall to prevent water from simply flowing off the side of the flashing within the masonry wall rather than being directed to weeps where it can flow out of the wall. Skip to Main Content. The cavity is closed with a proprietary cavity closer.

If you use thin.

Architectural Details Roofing Systems Standing Seam Roofing Standing Seam Roof Standing Seam Roofing

How To Install Polycarbonate Wall Google Search Hip Roof House Plans Hip Roof House Roof

Parapet Wall To Curtain Wall End

Https Architizer Com Blog Architectural Details Garden Studio Media 2142210 Roof Architecture Solar Panels Roof Architecture Details

Pin On Construction Information

Zintek Gutter Detail Flat Roof Design Zinc Roof Roof Construction

Overhangs Roof Construction Roof Detail Exterior House Remodel

Chimney Flashings Roof Cladding Home Construction Building Roof

Pitched Roof To Brick Wall Huse

Pin On Construction Information

How To Install Endwall Trim For Union S Masterrib Panel Metal Roof Installation Roof Installation Roof Truss Design